Have questions or need a quote?

Get in touch with the team today.

Welcome to SUPFORGE Factory

ACOFORJADO has a 40-year history in China and is a trusted brand in the forging industry. Our main business is to customize forged parts for customers around the world.

We offer not just high – quality forging components, but also a full suite of services. This includes heat treatment to enhance mechanical properties, top – tier machining, and various surface treatments like electrophoresis, powder coating, and electroplating. We’re able to supply fully – finished industrial metal products.

For special metals such as stainless steel, aluminum, and titanium alloys, we can provide excellent forging solutions and products.

With rich experience and a commitment to quality, We are able to meet the diverse needs from different industries, ensuring every project is done precisely and efficiently.

40 Long Years Of Manufacturing Excellence With Quality At It’s Best !

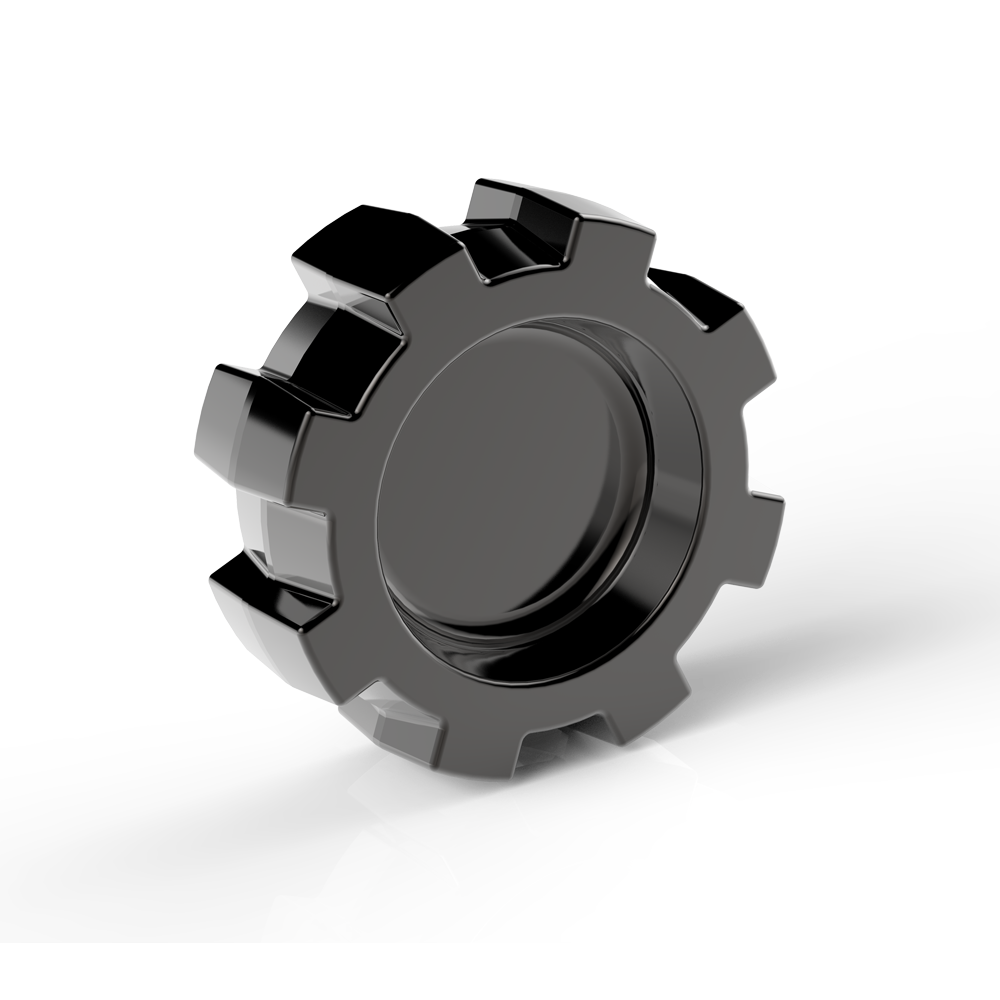

Forging ability

We have one 3,000-ton, two 1,600-ton, one 1,000-ton and two 630-ton forging machines.

0-100KG products

We are able to produce products weighing 0-100 kg independently

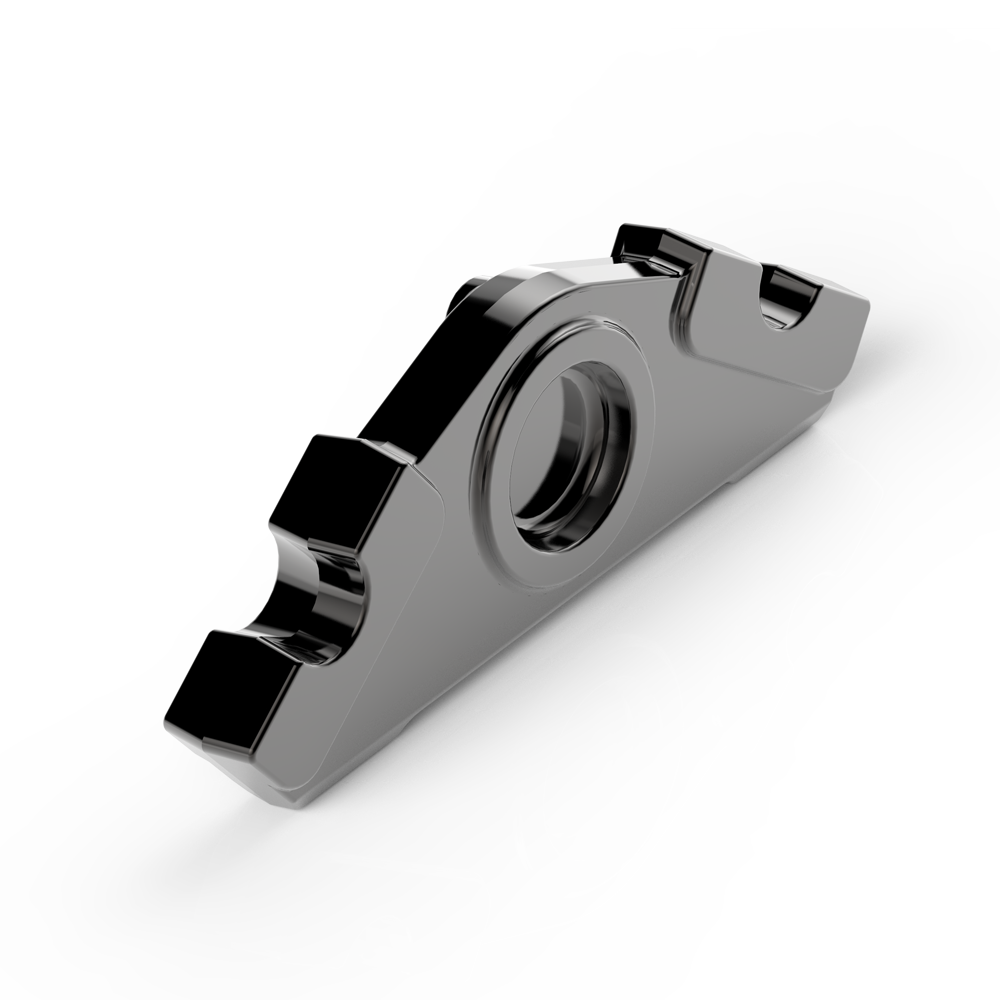

Special-shaped forging

For parts with complex shapes, we can also design molds and develop special production supplies to meet the needs of our customers

Casting to forging

For casting parts that have been used in some industries in the past, we are able to help them design and change them into a forging process to reduce the pitting and low strength that comes with casting, and most importantly, to reduce costs

Industries We Serve!

Agricultural machinery

Lifting Equipment and Fork Lifts

Oil and GasIndustry

Mechanical Engineering

Truck industry

Rigging and Hoisting Equipment

Mining Machinery

Port Machinery and Equipment

Conveyor Chains

Shipbuilding Industry

Construction Industry

Coal Mine Chains

Aerospace industry

Customized service

Our professionalism will contribute to your success.

Digital Simulation Design

Using professional simulation software Deform, we conduct digital design and simulation analysis of forging dies, accurately predict key forming parameters, optimize die structure, and ensure precision and durability.

Professional Product Guidance

Senior engineers provide full-process guidance, drawing and verifying 3D die drawings in detail based on requirements.

Professional advantages

Perfect Machining Capabilities

We can deliver 100% finished, machined forged products to customers.. Whether it’s complex precision parts or large – scale components, we have the expertise and resources to meet your demands..

Tailor Uniquely Yours Molds

In the field of forging products, every customer has unique needs. With our profound industry experience and exquisite technology, we tailor make unique molds for each customer.

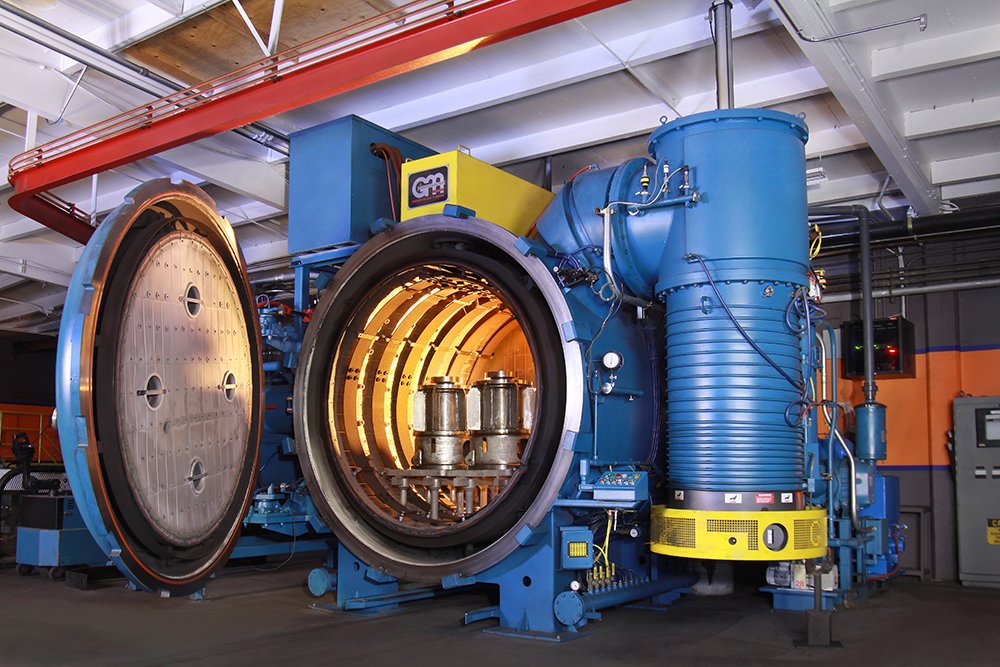

Professional heat treatment

We can provide professional heat treatment services according to the customers’ requirements

quenching ; tempering ; normalizing ; annealing ;

Quenching and Tempering

Case Carburizing high-frequency quenching

Change casting to forging

We provide you with technical support to change your cast parts into forged parts.

Higher Strength: The Core Advantage of Forged Components Superior Toughness: A Key Trait of Forged Parts Better Precision: The Key to Reducing Processing Costs

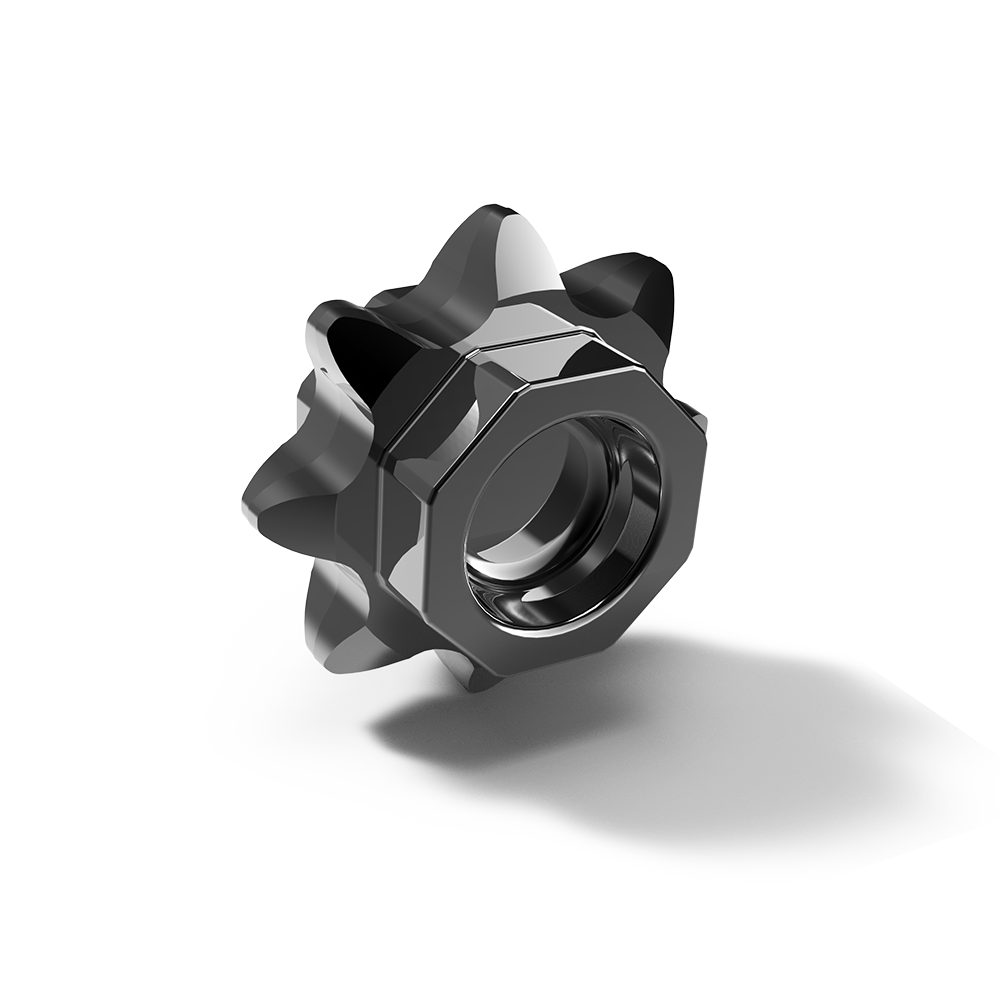

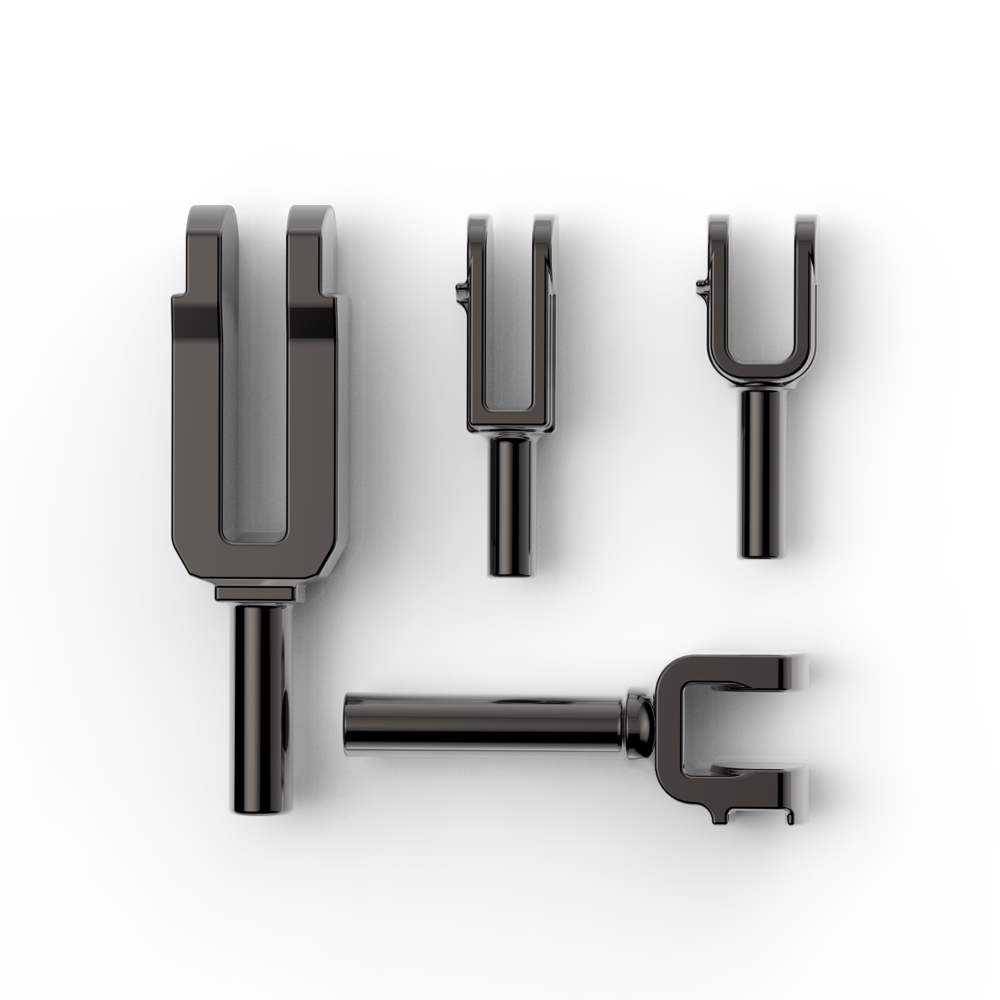

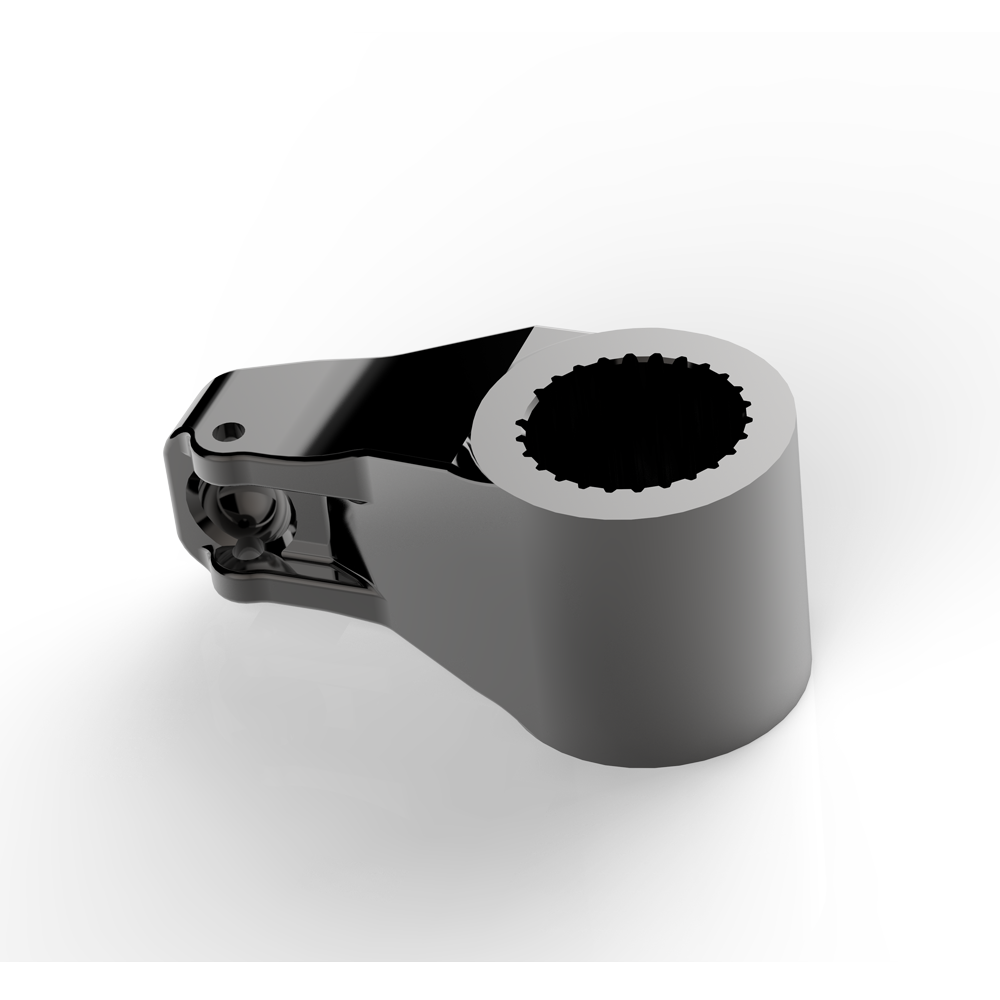

Products

Forged chains

Agricultural machinery

Truck accessories

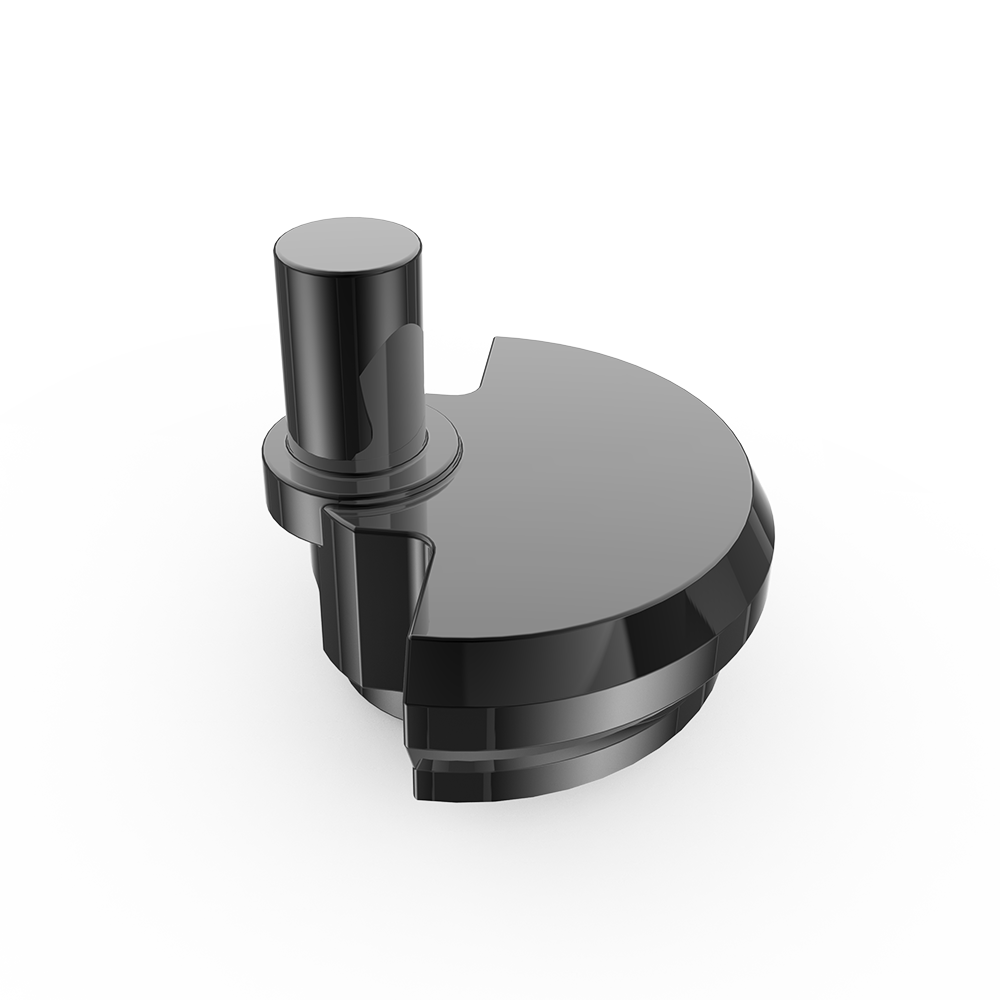

Hydraulic Cylinder Accessories

Construction machinery

Our partners